Simulation software for engineering projects come in different forms: from generic programming tools, such as MATLAB/Simulink, Python or Labview to speciallized tools such as Ansys, AGI’s STK, Simscale or others they all perform cruicial tasks for the engineers during the product development lifecycle.

What happens when simulation software is not connected to a Single Source of Truth

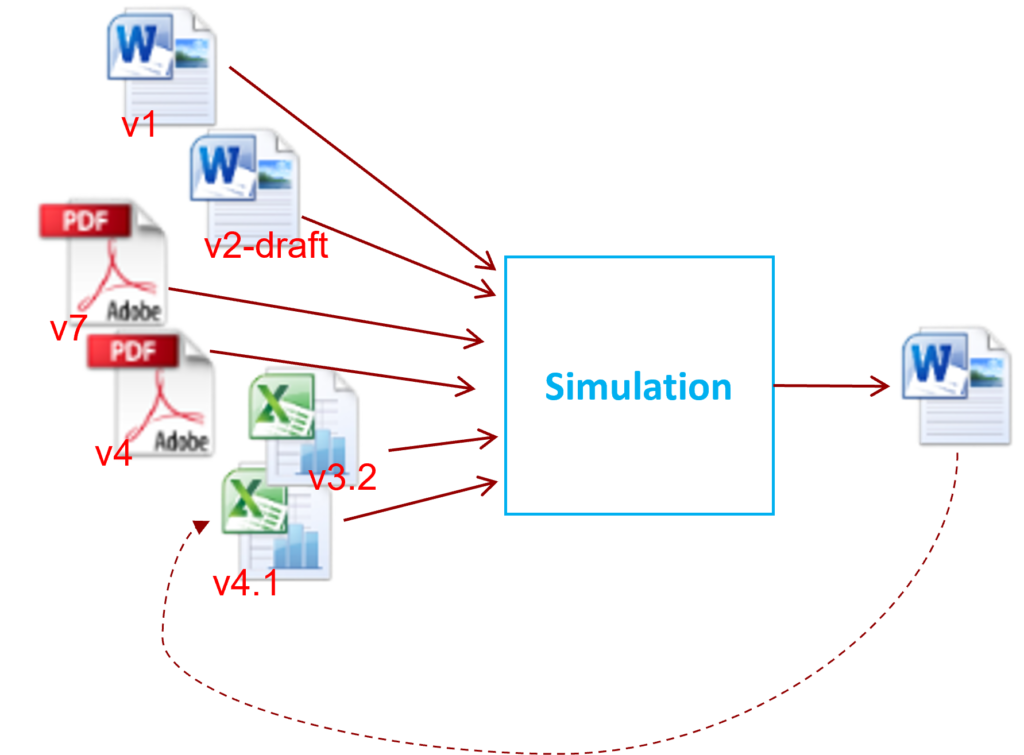

Tracitionally the inputs for a specific simulation are gathered manually by an engineer from different document in multiple versions:

This approach has many downsides:

- Finding the right inputs in multiple documents is timeconsuming

- When any of the inputs change, the simulation engineer needs to update the simulation file with the new inputs to re-run the simulation

- Traceability of data inputs, simulations run and outputs is often lost

- The simulation engineer might not be aware that an input has changed; making the simulation and its outputs outdated

- Preparing simulation result reports is time consuming and error prone

The data-driven approach to simulations

The more robust and time-saving approach to simulations is a digital thread that connects a Single Source of Truth for versioned input and output parameters to the simulation file:

By using such an Engineering Information Management (EIM) System integration, the following benefits become obvious:

- The simulation input and output parameters are versioned and linked in the EIM, avoiding mistakes

- The EIM constantly monitors for changes of input parameters, indicating when a simulation needs to be re-run

- Re-running a simulation will with a single click always rely on the most-up-to-date inputs, saving engineering hours

- Full traceability is given for every input and output parameter

- Simulation reports can be automatically generated in the EIM without the need for manual work