What are PLM/PDM Systems, and what is their history?

Product Lifecycle Management (PLM) and Product Data Management (PDM) systems have been invented in the 1980s, to complement CAD-Systems with core functionalities for Geometric Design Management:

- Manage CAD-files and their versions/configurations

- Manage Bills of Material (BOM)

Why were they introduced?

The key realization at the time was, that storing CAD files on local file systems created a configuration nightmare. It was unclear which CAD file was used for which product build and manually created assemblies and parts lists were very error prone.

Introducing a central repository for CAD-file versioning and the creation of BOMs that could feed into the production and purchasing of physical parts was a game changer for the industry.

Over the years, CAD-System providers like Dassault, Siemens, PTC and others have expanded the functionalities of these PLM/PDM tools such as:

- Document Management

- Metadata Management

- ERP and MES integrations

In short: PLM/PDM systems are CAD systems with an added layer of file- and parts-management.

Why is Systems Engineering not adequately covered by PLM?

Even though the words “product lifecycle” in PLM suggest that all engineering aspects are covered by these systems, PLM systems cover only the Geometric Design Management aspects of Engineering. Modern products however are complex systems that involve many engineering disciplines. Typical data that are critical for product design, but you won’t find in PLM/PDM systems:

- The breaking distance of a train and which parameters (speed, friction coefficient, etc.) it depends on.

- Formula, how to calculate the charging time of a car battery.

- Forecast of verification completeness (how many tests have been executed already).

- Traceability of power-requirement to the motor power consumption.

- Evolution of critical mass over design time.

- …

What these elements have in common, is that they belong into the roam of Systems Engineering (SE) and PLM tools are no systems engineering tools.

How Engineering Information Management Systems complement PLM

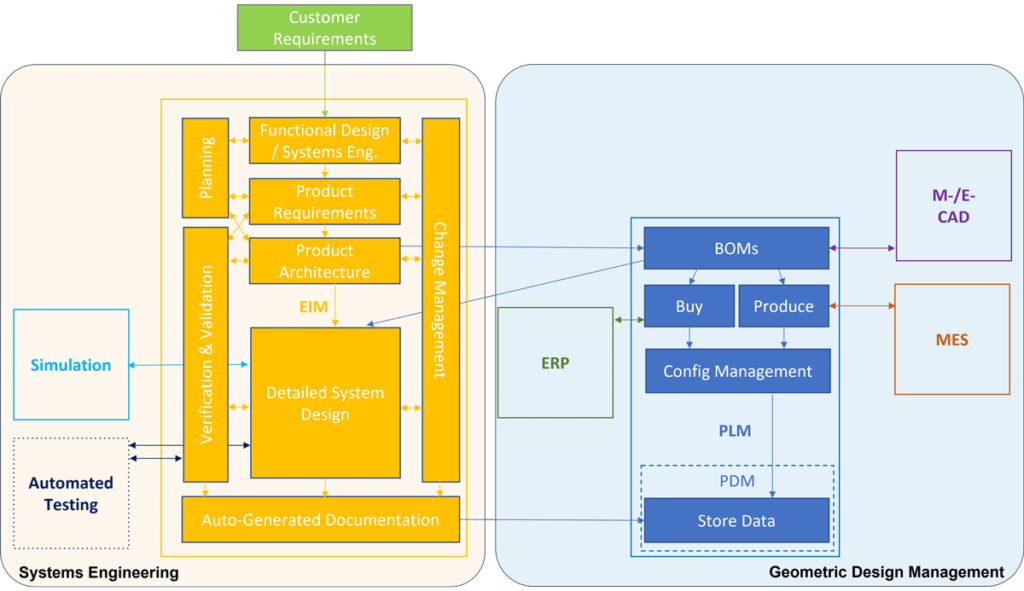

It becomes obvious that PLM systems need to be complemented by a tool that manages engineering data and all other aspects of Systems Engineering. These tools are called Engineering Information Management (EIM) systems:

EIM Systems work alongside:

- PLM Tools (such as Dassault’s 3D Experience, Siemens Teamcenter, Duro Labs, etc.) that mainly manage CAD-parts, Bills of Material (BOMs), procurement, as well as the connections to ERP, CAD and MES tools.

- Simulation Tools (such as Matlab, Python, Anysis, AGI’s STK, etc.)

- Automated Testing Tools (such as Epsilon 3, Terma CCS, etc.)

EIM + PLM

In summary: EIM and PLM systems complement each other well and together allow engineers to develop systems and geometric design that answer to customer requirements, saving organizations time and avoiding critical mistakes.